Product Categories

Industrial fabric popular science series Two---Coating and film

Coated fabric is a new type of material that has developed extremely rapidly in recent years. It is a composite material that integrates structural mechanics, material science and design, and is a new economic growth point for the textile industry. Polyvinyl chloride (PVC) has good aging resistance and is a cost-effective coating material.

At present, there are three types of coating fabric manufacturing processes, namely laminating method, calendering method and coating method. The laminating method is a processing method in which the upper and lower layers of the formed PVC film are heated and laminated with the middle base fabric layer under the pressure of a hot roller; The calendering method is a processing method in which various raw materials such as PVC powder and liquid plasticizer are fully stirred and bonded to the base fabric under the pressure of a high temperature hot roller. The coating method is to evenly coat the liquid PVC slurry on the front and back sides of the base fabric with a scraper, dry and plasticize it to make it completely integrated into a whole, and then cool and shape. The products produced by the laminating process and the calendering process have poor peel strength, while the products produced by the coating process can be added with a certain adhesive, and the products have better peel strength. The comparison is as follows:

PVC laminated fabric | PVC semi coated fabric | ||

Composition | base fabric and coating | base fabric and a PVC film | base fabric,coating and PVC film |

Coating | The main component of the coating | PVC film | PVC paste resin + PVC film |

Craft | The paste-like PVC slurry poured | The PVC film attached to | first sizing, |

Advantage | high adhesion | high production efficiency | high production efficiency |

Disadvantage | poor air tightness | short service life | short service life |

Service life | long | short | short |

production efficiency | low | high | high |

Air-tight | poor | good | good |

Style | Both the front and back are relatively flat | The front is flat | The front is flat |

The addition of plasticizers can reduce the force between PVC molecular chains and reduce the glass transition temperature, flow temperature and melting point of the crystallites contained in the PVC plastic. The plasticizer can improve the plasticity of the resin, make the product soft and have good low temperature resistance.

Because the material contains plasticizers, it is susceptible to mold attack. The anti-mold agent is added to kill the mold and prevent the PVC material from being mildewed and rotten.

Fillers are solid additives used to improve the performance of composite materials and reduce costs,its functions are:

① reduce the shrinkage of molded parts, improve the dimensional stability, surface finish, and smoothness of the product;

② effectively adjust the resin viscosity;

③ It can meet different performance requirements and improve wear resistance. Most fillers can improve the impact strength and compressive strength of the material, but cannot increase the tensile strength;

④ Improve the coloring effect of the pigment.

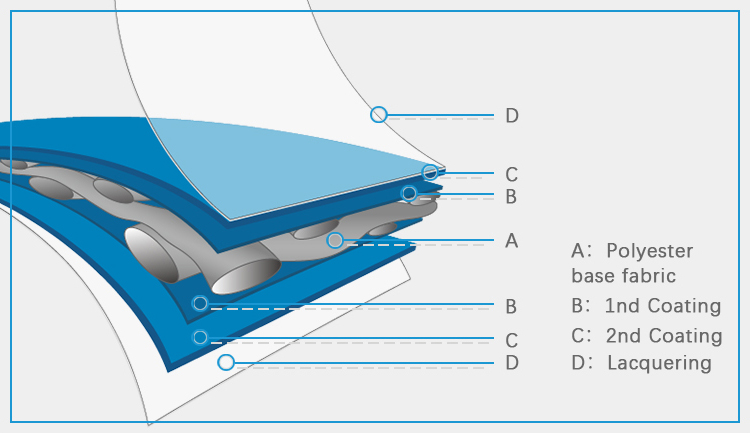

PVC coating/polyester fabric is mainly PVC coated (or laminated) on polyester fabric to make the fabric have color, strength and water resistance. PVC/polyester fabric can be welded frequently. Microwave can be used when welding. Toughening agents are generally added to PVC. Microwave can remove the toughening agent in the weld, and the strength of the weld is better than that of PVC/polyester fabric itself. PVC/polyester fabric has the advantage of low cost because of its cheap materials, convenient transportation and storage, and easy processing and construction.

You may also like

- PVC knife coating fabric - PVC Conveying Belt

- Construction Snow Removal Lifting Tarps 23' x 23' & 8 Loops - 18 Oz PVC Coated Vinyl Fabric

- 1000d Heavy Duty Dump Truck Mesh Tarp,Pvc Dipped Mesh,Polyester Mesh Fabric

- Clear Marine Vinyl Enclosure large transparent curtain

- Airbag parachute fabric ultra lightweight lumber tarp

- PVC coated tarpaulin Cape embossi-Orange on top

- Heavy Duty PVC Coated Vinyl Lumber Tarp For Truck Cover Waterproof PVC Laminated Lumber Tarps Cover

- PVC knife coating fabric inflatable material-Positive blue

- 5' x 7' Clear Fire Retardant PVC Tarp

- Strong Transparent Clear Vinyl Tarps Clear Plastic Tarp

Others also viewed

- Waterproof canvas detailed introduction

- What is PVC Tarps?

- How to Care for PVC Tarps

- The Details Of The Correct Use Of Tarpaulin Tents

- what is tarping in trucking?

- DIY PVC Tarp Pole

- The Difference Between PE And PVC Tarpaulin

- How to buy Heavy Duty PVC Tarpaulins

- Jumtarps Tell You How To Choose The Right PVC Vinyl Tarp

- Why PVC material tarpaulin is so popular