Product Categories

what would cause pvc tarpaulin to discolor

what would cause pvc tarpaulin to discolor

PVC tarp is perhaps the most well-known PVC item generally utilized. However, during the time spent on pipe creation, there are consistent issues of pipe discoloration. Albeit now and again the color doesn't influence the utilization of pipes, it's anything but an extraordinary effect on the style and deals of pipes. During the time spent utilizing, the discoloration of pipes can even influence the picture of the organization's items. So for what reason do pipes have discoloration issues? simply look over this Article.

The connection between Molecular Structure and Color of PVC

1. Since PVC tar is a sort of thermosensitive plastics, light soundness is poor. Under the activity of warmth and light, the branch chain goes through HCI response and polyene structure particles. At the point when the quantity of formed twofold bonds in the primary chain isn't excessively enormous, there will be a following chromatic variation. Hydrogen chloride initially responds with the expected corrosive dynamic substances around it, and the formed twofold bonds become another dynamic situation in the sub-atomic chain of PVC and are started by light. At the point when the free extremists of macromolecules are framed, PVC is defenseless against oxidation and color change.

2. There are some low sub-atomic weight parts in PVC resin. The warm security of the polymer was reduced. The disintegration component of PVC incorporates a free extreme instrument, ionic system, and single-particle mechanism. In expansion to stabilizers, the decay of PVC may likewise be influenced by the nature of PVC sap itself, like whether there are over-the-top lingering initiators in PVC tar.

3. On the off chance that there are a few debasements in the polymer, like initiator, impetus, corrosive, antacid, and so on which are included in the cycle of polymerization, or water is ingested during capacity and transportation, the steadiness of the polymer will be decreased.

Since these substances can cause atom particle corruption response, CPE contains more Cl2, HCl, and other low sub-atomic substances, which is not difficult to speed up the warm deterioration of tar. In this way, the yellowing issue of certain pipes can be disposed of by expanding the measure of stabilizer in the PVC+CPE framework with helpless strength.

4. PVC tarp is a blending framework comprising of PVC as a nonstop stage, multi-stage polymer and combination working warmth stabilizer, light stabilizer ointment, filler, and colors. At the point when PVC tarp is presented to regular habitat, when the PVC part dehydrochlorination, the first segment of calcium carbonate will be changed into another segment of calcium chloride, which scatters in the oxidative debasement layer and structures a potential water ingestion position. One reason why pipe gets yellow.

5. Notwithstanding temperature and stress, plastics are corrupted by shear pressure and tractable pressure during the time spent high blending, cold mixing, and expulsion before framing.

When addressing chromatic deviation, a solitary strategy can not manage the issue satisfactorily. In the following article, I will share the solutions. see you sometime later!

PVC tarpaulin is a well-known shade texture, which is effectively used to ensure different structures, gear, vehicles from the adverse consequences of climate conditions. Such material is described by expanded dependability, protection from mechanical pressure.

On account of this, the ubiquity of the texture has been at an undeniable level for quite a while. The remarkable construction of the material guarantees the obstruction of the PVC tarpaulin to dampness infiltration. Simultaneously, normal air trade isn't hampered.

These characteristics well recognize items made of PVC tarpaulin from those sewn from built-up film or polyethylene. Highlights of the creation, benefits, and extent of use of PVC tarpaulin will be depicted underneath.

Highlights of the production of PVC tarpaulin.

The principal part that is utilized to make such a tarpaulin is polyvinyl chloride. To build warm security, pliancy, and adaptability, assistant materials (inhibitor, plasticizer) are likewise added.

To guarantee mathematical security, non-combustibility, a pale gum is added to the piece. PVC tarpaulin likewise includes wear opposition, strength, and scraped spot obstruction.

Sorts of PVC tarpaulin.

Current hardware and helper materials make it conceivable to deliver PVC tarpaulins of the accompanying sorts:

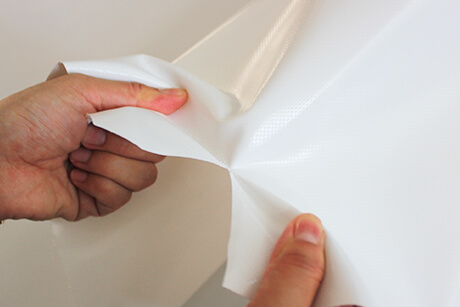

PVC covered tarpaulin: made during the time spent overlaying PVC film and unique texture (polyester);

PVC covered material (genuinely covered tarpaulin): during creation, PVC melts to a fluid state, after which this combination is applied to the texture. To eliminate abundance fluid mass, the material is passed between the cutting edges;

Hot soften PVC tarpaulin: PVC film is liquefied at high temperatures during the assembling interaction and afterward covered into the polyester texture. To guarantee a better bond, high-strength cement is utilized before cover. The primary benefit of hot liquefy is accessibility.

The thickness of the tarpaulin goes from 350 - 600 g/m². During the assembling cycle, the material can be also treated with exceptional impregnations.

Because of this, the fabricated items have the best qualities. The standard width of PVC tarpaulin is 90 cm. Notwithstanding, if fundamental, the client can buy material of non-standard measurements.

When in doubt, such items are utilized for the execution of non-standard orders. As referenced above, PVC tarpaulin can have various impregnations. To make it simpler for the purchaser to pick items, producers partition them by color: from light yellow (flame resistant) to green (waterproof).

Properties of PVC tarpaulin.

PVC tarpaulin, made as per GOST guidelines, has the accompanying positive highlights:

protection from abrupt temperature changes;

imperviousness to fire, high hygroscopicity;

protection from wear, so the material isn't anxious about mechanical harm.

Toughness is another positive element of the material. Many are of the assessment that coverings have no particular timeframe of realistic usability. This is to be sure of the situation. PVC tarpaulin can be utilized for a very long while

You may also like

- 16 inch Rain Flap PVC Vinyl 27 ft x 16 ft Lumber Tarp

- Oversized Load Tarps 26 ft X 30 ft LUMBER TARP 3 ROWS D-RINGS

- 10 OZ Black 7'*14' 7'*16' 7'*18' 7'*20' 7'6"X38' Cargo Dump Truck PVC Coated Polyester Vinyl Mesh Tarp Tarpaulin

- Industrial Construction Protection Pvc Coated Mesh Fabric Tarp

- Heavy Duty Lumber Tarp 24'x 28'(8' Drop Flap) 18oz Tarp

- 18 oz heavy duty waterproof pvc coated tarpaulin light weight truck lumber tarp

- PVC tarpaulin-Diamond Embossing

- Heavy Duty Lumber Tarp 16'x 28'(4' Drop Flap) 18oz Tarp

- Customized PVC steel tarps lumber tarps

- PVC Clear Vinyl Tarps PVC Transparent Tarpaulin

Others also viewed

- Tent Fabric Types: Technical Analysis of PVC Coated Fabrics & Materials for Heavy-Duty Tents

- What is PVC Tarps?

- How to Build a Shelter with PVC Tarp and Rope

- Commonly used tarp sizes

- How to choose a tarp tent

- Market Analysis Report on Lumber Tarps in the U.S.

- Something About PVC Tarpaulin

- Is PVC Tarpaulin Waterproof?

- Jumtarps company participated in the Mid-America Trucking Show 2025

- The difference and pros and cons of polyethylene tarpaulin, PVC tarpaulin, and canvas tarpaulin.