Tarps News Categories

Tent Fabric Types: Technical Analysis of PVC Coated Fabrics & Materials for Heavy-Duty Tents

When people marvel at the sky-obscuring canopies of music festivals, the colossal temporary structures towering beside industrial warehouses, or the grand, light-filled installations at high-end exhibitions, the core secret behind these "temporary giants" lies in the fabric that covers them. These large, heavy-duty, rental, and exhibition tents have long surpassed the lightweight simplicity of ordinary camping tents. The materials they require are a perfect fusion of strength, durability, environmental resistance, and functionality. This article will delve into these key materials, particularly the industry backbone—PVC coated fabric.

I. Core Material Systems

1. Base Fabric Engineering

High-Tenacity Polyester (PET):

95%+ industrial tent applications

Tensile strength: ≥800 N/5cm (ISO 13934-1)

UV resistance: TiO₂-enhanced yarns

Critical Weaving Techniques:

| Base Type | Thread Density | Tear Resistance | Use Case |

|---|---|---|---|

| Knife-coat base | >22 threads/cm² | >80N (ASTM D2261) | Exhibition tents |

| Biaxial warp-knit | 2000+ N/5cm | N/A | Aircraft hangars |

2. Advanced Coating Technologies

PVC Knife-Coating System (Industry Standard):

[Adhesive Layer]

Plasticized PVC → Fiber penetration (0.3mm)

↓

[Light-Blocking Core]

Carbon black (OD≥4) or TiO₂ interlayer

↓

[Surface Armor]

PVDF film → Weatherproofing + Self-cleaning

Key Performance Advantages:

Wind load resistance: >2.5 kN/m²

Abrasion cycles: >10,000 (ISO 5470)

Service life: 12-18 years outdoor

II. Light-Blocking Technology Deep Dive

How Tent Blackout Fabrics Work

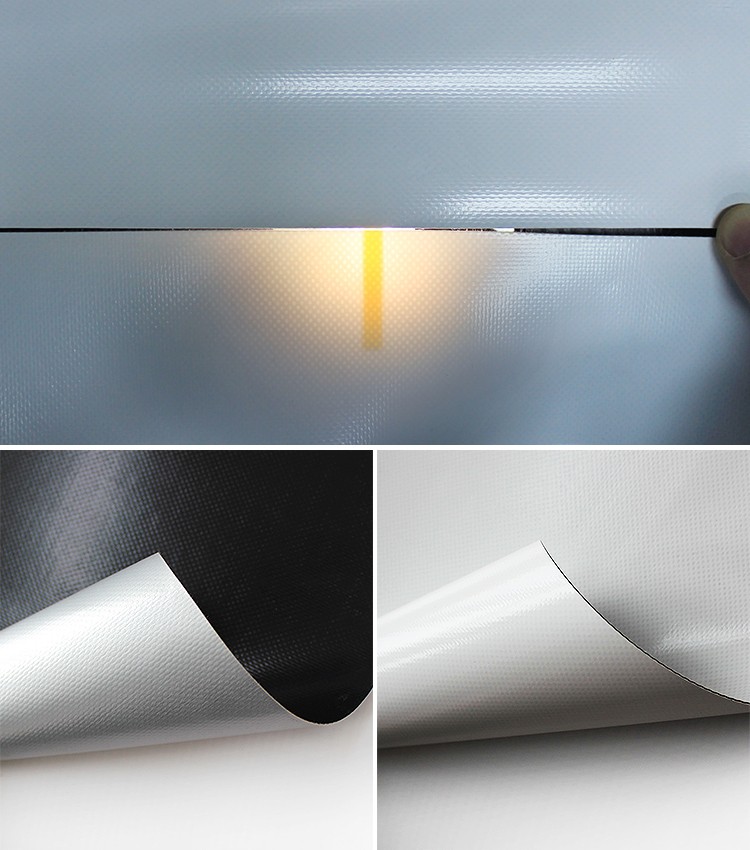

[Cross-section diagram showing fabric layers with light-blocking interlayer]

Fig 1. 3-layer PVC knife-coated fabric structure

Optical Performance Data:

| Method | Material | Transmittance | Industry Application |

|---|---|---|---|

| Absorption | Carbon black | <0.1% | Photography darkrooms |

| Reflection | Rutile TiO₂ | <5% | Medical isolation tents |

III. Material Comparison Guide

Heavy-Duty Tent Fabric Selection Matrix

| Property | PVC Knife-Coated | PU Polyester | Fiberglass/PTFE |

|---|---|---|---|

| Cost per m² | $12-18 | $8-14 | $90-150 |

| Light Blocking (OD) | ≥4.0 (interlayer) | ≥3.5 (coating) | ≥4.2 |

| Flame Rating | EN 13501-1 B1 | EN 13501-1 B-s2 | EN 13501-1 A2 |

| Tensile Strength | >1200 N/5cm | >800 N/5cm | >3000 N/5cm |

| Service Life | 12-18 years | 5-8 years | 25+ years |

IV. Application-Specific Solutions

✅ Industrial Warehouse Tents

Recommended: 1100D PVC knife-coated fabric with:

0.2mm carbon black interlayer

PVDF topcoat (contact angle >110°)

Minimum specs: 1800 N/5cm warp strength

✅ Festival Rental Tents

Optimized choice: 650g/m² PVC fabric with:

50,000+ flex cycles (ISO 7854)

Anti-microbial treatment

V. Sustainability Innovations

Eco-Friendly Material Roadmap

1. Phthalate-free plasticizers (Bio-based ECOZO™)

2. Recyclable PU systems - Closed-loop processing

3. Self-healing coatings - Microcapsule technology

Industry Insight: 2026 PVC tent fabric recycling rates projected to reach 45% in EU markets (ETFA data)

Technical References

ISO 13934-1:2013 Tensile strength testing

ASTM G154 QUV accelerated weathering

EN 13501-1 Flame resistance standards

you may also like

- Customized Clear Curtain Plastic Curtain Wall Clear Vinyl Curtains

- PVC knife coating fabric - Cover Tarpaulin Red

- PVC knife coating fabric inflatable material-Beige blue

- PVC knife coating fabric inflatable material-Light sky blue

- Waterproof Greenhouse Transparent Clear Poly Vinyl Tarp Reinforced Plastic Tarp

- Transparent PVC Tarpaulin Super Clear PVC Fabric

- PVC knife coating fabric raw material for truck cover-Navy blue

- 20' x 7' Baby Grande Clear Vinyl Outdoor Shades - Fire Retardant Clear Vinyl

- 24' X 20' (8' Drop & Flap) Lightweight Flatbed Trailer Lumber Tarp - 14 Oz. Black Tarp

- Clear Tarp Transparent PVC Tarpaulin

others also viewed

- what would cause pvc tarpaulin to discolor

- PVC Tarp - Why Are Plastic Tarps Blue?

- Commonly used tarp sizes

- Professional Q&A on the application of pvc fabirc raw materials---Ms. Hallen, sales manager of jumtarps

- Everything you know about pvc tarpaulin

- How to eliminate the static electricity of the pvc

- The difference between PVC Coated Fabric and PVC Laminated Fabric

- How Long Will A PVC Tarpaulin Last Outdoors?

- Custom Heavy Duty Or lightweight PVC Vinyl Dump Flatbed Truck Tarps & Covers For Sale

- Clear vinyl Detailed introduction