Tarps News Categories

Identifying the quality of tarpaulins involves assessing several key factors. PVC-coated fabrics, especially PVC waterproof tarpaulins, are essential coverings in industries like transportation and warehousing. With features such as wind resistance, durability, and abrasion resistance, canvas materials are in high demand across various sectors. In recent years, PVC-coated fabrics have become widely used in applications ranging from automotive and marine covers to construction site tarps and camping tents, owing to their exceptional qualities.

PVC-coated fabrics stand out as top performers among tarpaulin materials due to their excellent resistance to mold, noticeable waterproofing, superior flexibility in low temperatures, high strength and tensile properties, resistance to corrosion and aging, and lightweight nature. They are manufactured using methods like heat sealing and sewing.

Assessing the quality of PVC-coated fabrics involves focusing on several aspects:

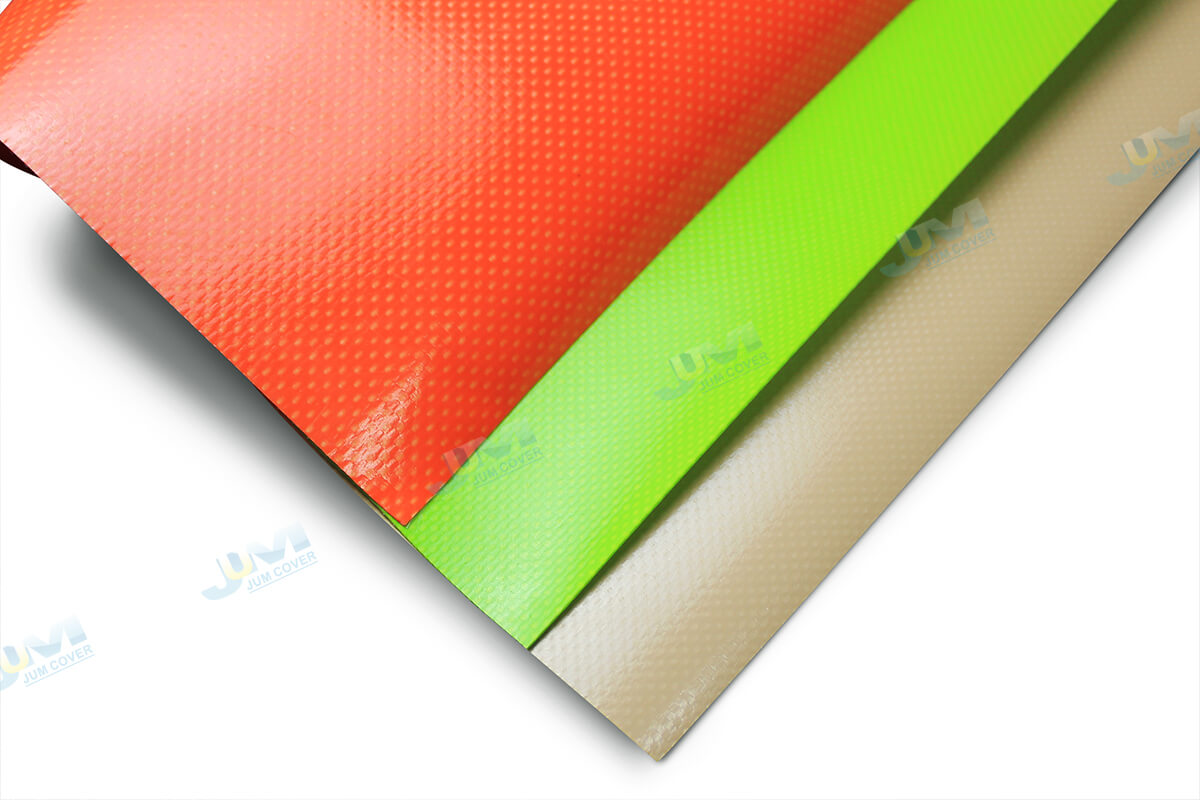

1. **Appearance**: High-quality PVC-coated fabrics exhibit a vibrant color with a glossy finish. One side is smooth, while the other may feature granular textures, indicating proper resin composition and temperature control during production. Lack of pinholes suggests high resin density, ensuring excellent resistance to aging and a longer lifespan.

2. **Tensile Strength**: Pay attention to the fabric's tensile strength, which is influenced by material composition and weaving techniques. Fabrics with higher yarn density generally have better tensile strength.

3. **Waterproof Performance**: Superior waterproofing is crucial. Absence of pinholes indicates good material quality, with high resin content and density contributing to enhanced waterproofing.

4. **Texture**: Despite appearing moderately thick, high-quality PVC-coated fabrics should feel soft to the touch. This softness is achieved through high resin content and superior processing techniques, eliminating any roughness.

5. **Production Process**: PVC-coated fabrics are typically produced using vertical machines, ensuring high-quality raw materials are used. The production process involves straightening and feeding fabric into the machine, applying PVC material on both sides, drying, trimming, cutting, and packaging. Vertical machines demand high-purity raw materials and produce slightly pricier but purer PVC-coated fabrics.

6. **Performance Characteristics**: PVC-coated fabrics are made of polyester filament as the base material, with PVC coating on both sides. They boast a smooth surface, vibrant color, and various properties including waterproofing, fire resistance, corrosion resistance, mold resistance, cold resistance, heat resistance, UV resistance, and aging resistance.

By considering these aspects, you can develop a discerning eye for selecting high-quality tarpaulins, enabling you to judge their quality at a glance.

you may also like

- PVC knife coating fabric inflatable material-Lemon yellow

- PVC knife coating fabric inflatable material-Green grass

- Clear Transparent PVC Tarpaulin Vinyl Tarp clear divider curtains industrial heavy curtains

- Clear Vinyl Tarps

- Wateproof Fabric Flatbed Lumber Tarp For Heavy Duty Truck

- 10' x 26' Clear Vinyl Tarp - 20 MIL - Fire Retardant Clear Vinyl

- 60% shade PVC Vinyl Black Mesh Tarp Dump Truck Tarps

- 16' X 18' Heavy Duty Flatbed Trailer Steel Tarp - 18 Oz. Black Tarp

- Heavy Duty Waterproof 610gsm PVC Coated Tarpaulin

- Custom Heavy Duty Mesh Shade Tarp Near Me For Sale

others also viewed

- The Difference Between PE And PVC Tarpaulin

- How to maintain the PVC tarpaulin

- What Is The Best Material For Blackout Blinds?

- How Long Does Vinyl Tarp Last?

- How is PVC tarpaulin made?

- Instructions for using tarpaulin

- Characteristics and Performance of Knife Coated Fabric

- Jumtarps Tell You How To Choose The Right PVC Vinyl Tarp

- Role of the Base Fabric in PVC Tarpaulins

- Advantages of JUM Lumber Tarps and Flatbed Truck T