Tarps News Categories

1. Air permeability:

Tarpaulin must consider its breathability, especially military tent fabric. The influencing factors of air permeability include base fabric structure, density, material, type of waterproof treatment agent, resin adhesion amount and so on. As the amount of resin adhesion increases, the air permeability of the tarpaulin decreases. Of course, this is related to the treatment agent used. Most air-permeable tents are made of short fiber fabrics such as cotton, vinyl, and lacquer treated with paraffin wax or acrylic resin.

2. Tensile strength:

The tarpaulin must withdraw various tensions when it is used, such as the tension when it is tightened when it is fixed; it is subjected to additional forces such as wind, rain, and sand during use. Even if it is subjected to these external forces, it must maintain the original shape and not easily deform. This requires the tarp to have a higher tensile strength, and there should not be too much difference in tensile strength in the warp and weft directions. The tensile strength of large tents for inflatable buildings is extremely important. Generally, the base fabric is made of high-strength polyester, vinyl and other long-fiber fabrics. Generally, the base fabric is made of high-strength polyester, vinyl and other long-fiber fabrics, which are water-resistant treated with vinyl chloride resin and chlorosulfonated polyethylene resin. The strength of the product is mainly determined by the strength of the fiber material and the density of the fabric.

3. Elongation and dimensional stability:

Roof tents and large tents are often used under tension. The elongation of the fabric should not be too large, and its dimensional stability is determined by the creep characteristics of the material.

4. Tearing strength:

Tarpaulin damage is mainly caused by tearing, so tear strength is an important indicator of tarpaulin. The tear strength is related to whether the tarpaulin will be broken due to the action of flying foreign objects or due to some reasons, the holes will expand around after being formed, forming a large structural tear. Therefore, when the tension is large, the tarpaulin is required to have both high tensile strength and high tear strength.

5. Water resistance:

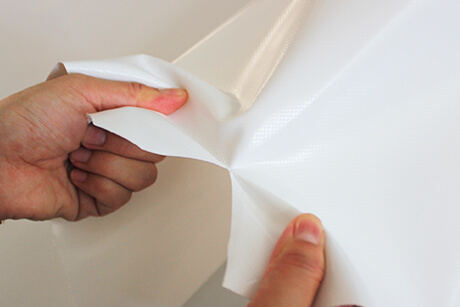

Water resistance is an important feature of tarpaulin. Through immersion treatment, vinyl chloride resin is filled in the gaps of the fabric tissue to form a coating film.

6. Flame retardancy:

From the perspective of safety in use, the tarpaulin should have better flame retardancy. Flame-retardant tarpaulin can be obtained by selecting flame-retardant fiber and flame-retardant base fabric; it can also be achieved by adding flame retardant to the coating. The flame retardant effect is directly related to the amount of flame retardant added.

you may also like

- Hot Sale PVC Coated OEM Mesh Tarp With Grommets

- 320gsm 0.225mm thickness 3x1.8 m glass pvc vinyl curtain

- PVC knife coating fabric Membrane - Blue

- 24' X 20' (8' Drop & Flap) Lightweight Flatbed Trailer Lumber Tarp - 14 Oz. Black Tarp

- Best waterproof Lightweight Heavy Duty 8 Feet Drop Lumber Tarp Steel Tarp trucking tarp

- Waterproof Pvc Tarpaulin Cover Insulation Clear Film Tarps Transparent Mesh Vinyl Tarp Prices

- Premium Mesh Roll Off Auto Tarping Systems

- 460G Keder Tent Material

- Lightweight Lumber Tarp For Flatbed Truck

- High Quality Black 18oz Viny Lumber Tarp

others also viewed

- How Long Does Heavy Duty Tarp Last?

- Folding method of pvc vinyl tarps

- canopy room has many advantages

- What kind of fabric is used for inflatables?

- Which Fabric Is Best For Roller Blinds?

- Advantages of JUM Lumber Tarps and Flatbed Truck T

- Which Colour Tarpaulin Is Best?

- PVC coated fabric and PVC laminated fabric

- Lumber Tarps

- Jumtarps In Mid-America Trucking Show 2023